Hey everyone!

I wanted to share a really cool project I worked on back in 2018 – my first ever engineering project – the Aqua Serving Robot. This journey was super exciting and full of learning experiences, and I think you’ll enjoy hearing about it. Let me introduce you to the key players in this adventure: my friend Ramandeep Singh, our mentor Professor Harpreet Singh Nagi, Mr. Virdi, and Lakhbir Singh.

The Beginning

It all started one evening in 2018 when my friend Ramandeep Singh, who was a year ahead of me, asked if I was interested in working on a project. I immediately said yes, eager to dive into something new. At that point, I had zero knowledge about programming or electronics. Yep, you heard that right – zero! But I was super eager to make something awesome. I always believed that in engineering, hands-on projects are where the real learning happens. Plus, the movie “3 Idiots” had a huge impact on me, and I thought, why not give it a shot?

The Idea

The idea was to create a robot that could serve water. Sounds simple, right? But we wanted to make it really cool. The Aqua Serving Robot would follow paths using programming and respond to water requests via a mobile app. On top of that, we wanted to make it eco-friendly, so we attached a dustbin to collect used glasses. A robot that serves water and cleans up after – how neat is that?

The Process

Even though we didn’t know much at the start, my team and I were determined to make this work. We spent countless hours brainstorming, designing, and experimenting. There were moments of frustration and excitement, but eventually, we figured things out. And let me tell you, the end result was pretty awesome!

I still have some blueprints of my first design that I created and showed to our mentor, Mr. Harpreet Singh Nagi. The day I showed the design to him was our first meeting. I came to know about Harpreet sir through Ramandeep Singh, who was from the mechanical department, while I was in the Computer Science department. The combination of building a mechatronics project was a perfect match, even though I didn’t know coding that well at the time. But I was eager to learn and always fascinated by PCB and other electronics stuff since childhood.

After finalizing the design, my friend arranged all the required materials, and we started building the robot in his hostel room. We didn’t know much about efficiency, design, or the overall outcome, but we started anyway. With the help of another friend, Mr. Virdi, who had access to a welding workshop through his parents, we arranged some materials, cut wooden sheets, and built the base of the robot. Within a couple of weeks, we had the structure of the robot painted and ready. Many times we didn’t have the necessary materials, so we roamed around the local market of Sirhind to get what we needed. This was my first time being involved in the whole process of arranging materials, talking to different shop owners, and making stuff with the team.

Here’s the first look after we finished up with the wooden work and paint. A fun fact: we made the head of the robot in the shape of Iron Man’s helmet, thanks to Mr. Virdi. Adding an Iron Man helmet gave a personal touch. Later, we added lights to the helmet’s eyes, and its ears were detachable.

Hardware Components

We used several key hardware components to bring our Aqua Serving Robot to life:

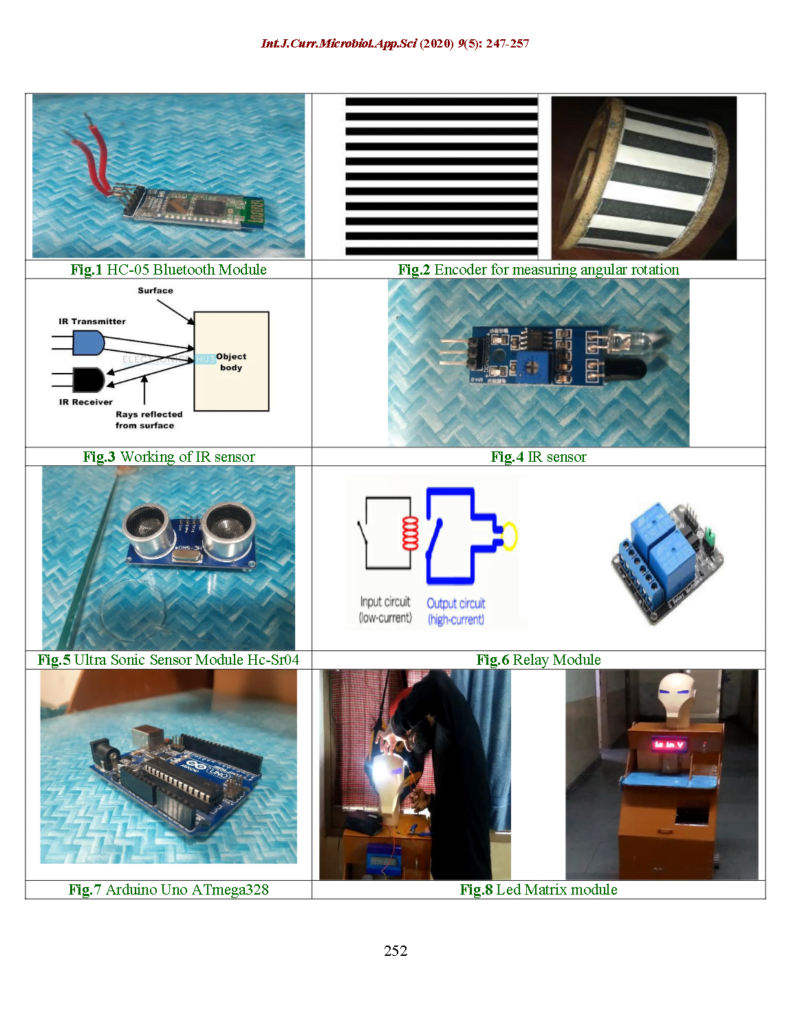

- Arduino UNO: The main control unit for the robot.

- Ultrasonic Sensor: Used for obstacle avoidance.

- IR Sensors: Two IR sensors for the dustbin conveyor belt and water pump start.

- Car Wiper Motors: Used as the main motors for the robot.

- Motor Drivers: Two parallel motor drivers for each motor.

- LED Matrix: For displaying messages.

- 5-Volt Water Pump: For serving water.

- Conveyor Belt Motor: To move the glass into the dustbin.

Attaching all these devices was the most interesting part for me. It wasn’t too hard to connect everything; we just had to connect the VCC and GND (ground wires) to the main power supply and the other sensor wires to the control unit.

Once the hardware was done, we dove into the coding part. Thanks to our mentor, Professor Nagi, who wrote the initial code and taught us how it worked. We experimented with the code, and this was when I started understanding the basics of programming. I began coding simple if-else loops and other small projects like LED pattern-making and playing with IR/ultrasonic sensors.

Navigation Technique Used

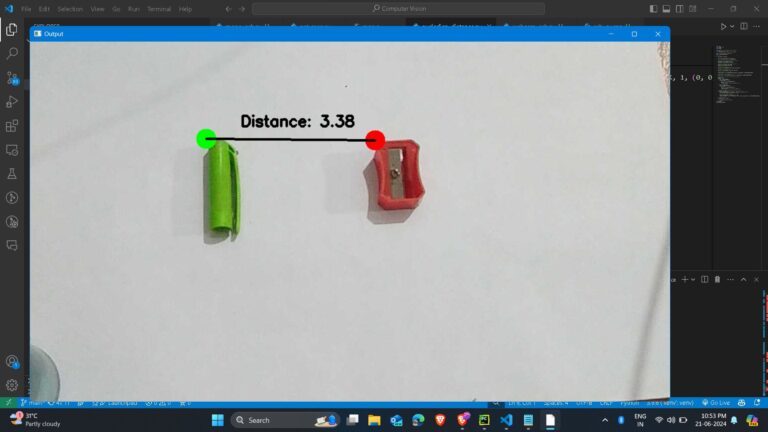

We used the wheel encoding method for navigation. The idea was simple: we attached a zebra strip with black and white lines to the robot’s wheels and placed an IR sensor above it. As the robot moved, the IR sensor counted the number of times black lines appeared (since the IR sensor emits infrared light, which is absorbed by black and reflected by white). This allowed us to determine the wheel’s circumference and estimate the distance traveled by the robot based on the number of wheel rotations. However, this approach had its issues. Wheel slippage could cause errors in estimation, which was problematic since even a slight shift in direction could alter the robot’s path.

This problem stuck with me and became the focus of my master’s thesis, which I’m currently working on. I aim to solve the navigation problem using Simultaneous Localization and Mapping (SLAM). More on this in another blog.

Working of the Robot

We created a mobile application with a button to call the robot. The robot connected to the mobile phone via a Bluetooth module attached to the Arduino UNO controller. When the user clicked the button, the robot followed a defined L-shaped path to reach the user. The user would then pick a glass from the robot’s tray and place it under the tap. An infrared sensor under the tap indicated that the user needed water, and the controller module sent a command to start the water pump. The robot filled the glass according to a pre-defined timing. After drinking, the user placed the glass in the robot’s bin, triggering a sensor that activated a conveyor belt to move the glass into the bin. The robot then returned to its original position.

Challenges

We faced several challenges during the project:

- Navigation Accuracy: The wheel encoding method had issues with slippage, causing errors in the robot’s path estimation.

- Complexity of Design: Our initial design was overly complicated with unnecessary wooden work and a conveyor belt for the dustbin.

- Scalability: The robot needed to be programmed for each specific table in a potential deployment scenario, making it less scalable for larger settings.

- Control Mechanism: Instead of using a mobile app, a simpler remote button for each table could have been more efficient.

The Result

Our Aqua Serving Robot turned out to be a huge success. It navigated paths perfectly and served water whenever someone requested it through the app. The eco-friendly dustbin attachment was a great addition – it collected used glasses and carried them away. It felt amazing to see our vision come to life.

What I Learned

Working on this project taught me so much:

- Teamwork: Collaborating with friends from different departments was incredible. Everyone brought something unique to the table, and together we created something innovative.

- Practical Skills: I learned the basics of programming and electronics, which were totally new to me. This hands-on experience was invaluable.

Sharing Our Experience

After our successful project, we didn’t just stop there. We organized workshops at our college to share our journey and inspire others. It was great to see other students getting excited about engineering projects and knowing that we could make a difference.

Going a Step Further

We even published a paper on our project titled “Development of a Cost-Effective Beverage and Food-Serving Robot for Hygienically Outcomes and Human Comfort.” You can check it out here. Plus, if you’re into coding and want to see how we did it, the code is available on

GitHub: https://github.com/BalveerSinghYT/Aqua-Serving-Robot.

Conclusion

The Aqua Serving Robot was more than just a project; it was a major milestone in my engineering journey. It showed me the power of determination, teamwork, and innovation. Looking back, I’m proud of what we achieved and excited about the future projects to come.

Thank You Note

I want to extend a heartfelt thank you to everyone who was part of this incredible journey:

- Ramandeep Singh: Your idea and leadership were the driving forces behind this project. Thank you for your constant support and encouragement.

- Mr. Virdi: Your expertise and access to the welding workshop were invaluable. The Iron Man helmet was a brilliant touch!

- Lakhbir Singh: Your help and enthusiasm throughout the project were crucial. We couldn’t have done it without you.

- Professor Harpreet Singh Nagi: Your mentorship and guidance were essential. You taught us so much about electronics and programming, and your support was a cornerstone of our success.

Thank you all for making the Aqua Serving Robot a reality. This project wouldn’t have been possible without each one of you.